Custom LED strip applications are rapidly transforming commercial architecture, demanding higher efficiency and smarter integration than ever before. Modern lighting projects require more than just standard illumination; they demand precision-engineered components that ensure longevity, energy conservation, and ease of installation. This article investigates the critical technical components—from PCB architecture to smart control protocols—that define a high-performance custom lighting system.

Core Architecture: Selecting High-Performance PCB and Chips

Customized PCB Design for Voltage Stability

Keeping voltage steady over long light lines is the main thing that sets even glow in a custom LED strip setup. Basic PCBs often face big voltage drops. This causes fading at the strip’s end and uneven power draw. Better custom strips use two-layer PCBs with 2oz copper thickness. This beats the usual 1oz standard. The thicker copper cuts resistance. As a result, it allows longer straight runs without a clear brightness fade. This helps save energy by cutting lost heat. Plus, smart circuit plans spread current evenly. So, they shield single parts from too much load.

High-Efficiency LED Chips: SMD5050 vs SMD2835

Picking the right chip type matters a lot for matching light output per watt and color accuracy. SMD5050 LED chips suit RGB and RGBW uses well. They have a bigger area for better heat release and a stronger glow. This makes them great for color-shift projects. On the other hand, SMD2835 chips focus on good heat handling in plain color setups. They often give 20-30% better power use than older types. Top makers like Epistar and San’an use fine build methods. These keep the color steady in a 3-step MacAdam ellipse. So, they avoid eye strain from off-color tones.

Smart Control Systems: DMX512 vs SPI Protocols

Advantages of Addressable LED Strips in Commercial Projects

For projects requiring dynamic visual effects, such as media facades or stage lighting, addressable LED strips utilizing SPI (Serial Peripheral Interface) protocols are essential. By integrating IC chips directly onto the strip, each pixel can be controlled independently to create complex animations. A prime example of this innovation is our Decorative Lighting Digital Strip DC5V SMD5050 Flexible RGBW LED Strip Light. Unlike standard RGB models, this flexible strip integrates the advanced SK6812 protocol with a dedicated white sub-pixel. This configuration not only delivers richer color saturation for branding but also provides pure, energy-efficient functional white light. This dual-purpose capability makes it an ideal solution for architectural projects that demand both atmospheric lighting and practical illumination from a single installation.

Choosing the Right Controller: Smart Integration

Adding a solid control setup links the parts to how users interact. DMX512 systems hold as the go-to for steady work in pro spots. They send signals far without mix-ups. The new push comes from mixing Wi-Fi with DMX. Controllers now allow cloud checks from afar. For example, top units handle Art-Net methods. This lets light planners put video right on LED grids. Such smart links mean you can plan and watch power use. In turn, this cuts running costs for big places.

Thermal Management: Aluminum Profiles for Longevity

The Role of Aluminum Channels in Heat Dissipation

Too much heat quietly shortens LED life. That’s why good aluminum profiles are a must for pro setups. An aluminum channel works as a solid heat puller. It takes warmth from the PCB and boosts diode life by up to 50%. For strips over 14.4W/m, a thick-walled aluminum profile is key. It keeps the heat point under safe levels. Also, these profiles add firm support. This stops the PCB from warping or splitting as time goes on.

Diffuser Options for Dot-Free Lighting Effects

To get a smooth, tube-like, straight light look, pair dense strips with the right cover. Milky polycarbonate covers spread the light to cut spots or dots. They make an even flow that’s nice to see up close. Clear covers let through about 95% of light. Milky ones allow around 85%. They trade a bit of glow for much better eye ease. This choice often wins in shops and guest spots where cutting glare counts.

Installation Innovations: Connectors and Waterproofing

Solderless Connectors for Rapid Site Installation

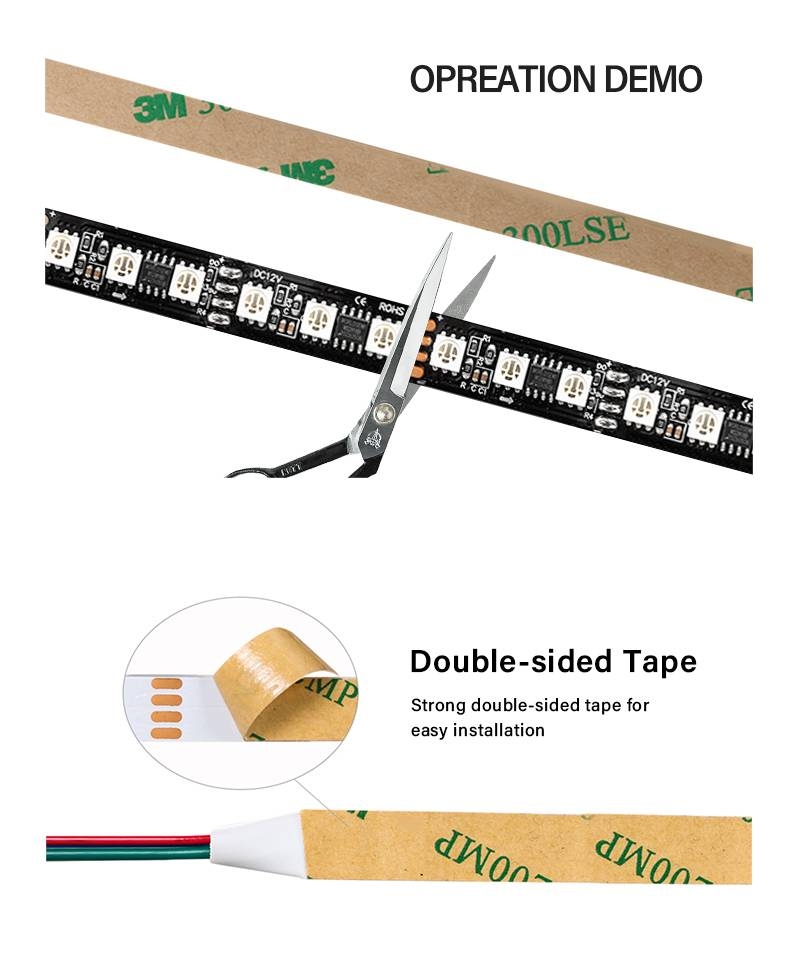

Cutting setup costs on site pushes the use of easy, no-solder join systems. New “hippoclip” or poke connectors let workers link cut pieces of IP20 or IP65 strips firmly. No need for solder tools. This cuts setup time by about 40%. These joints poke right into PCB spots for an air-tight hold. It stands up to shakes and heat shifts. In big jobs, this quickness saves money and speeds up finishes.

Advanced Waterproofing Techniques: IP65, IP67, and IP68

Picking the right Ingress Protection rating means knowing silicone covers versus epoxy layers. Silicone extrusion technology has mostly taken over epoxy for top outside uses. Silicone stays bendy and doesn’t turn yellow in sunlight. For water-deep or rough outdoor spots, IP68 comes from a full silicone fill molding. This keeps the custom LED strip fully closed from water and dirt. It ensures steady work even under water or in wild weather changes.

How SHIJILIGHTING Delivers Tailored LED Solutions

Comprehensive OEM/ODM Customization Services

At SHIJILIGHTING, we know ready-made items seldom fit special building needs. We focus on full OEM/ODM help. This includes tweaks to PCB size, voltage, like 12V/24V, and exact color warmth to match your brand. Our special design team aids fast test builds. We can send custom samples in just 3-5 days. Need set lengths for shelves or packs with your mark? Our bendy build steps meet your needs exactly.

Quality Assurance and Smart System Integration

We put system stability first by adding top parts like Epistar chips into our strict build flow. Our product range has advanced control tools. Take the SJ-M310RGB Wi-Fi UFO controller. It takes DC5V-24V wide power and works with phone apps easily. For big DMX jobs, our SJ-A310RGB systems keep perfect timing over thousands of spots. We back our quality with a 2-year warranty on items. This comes with tough QC steps where bad rates stay under 0.2%. Picking SHIJILIGHTING means choosing a helper for power-saving ideas and pro aid.

FAQ

Q: What is the best brand for custom LED strip lighting in 2025?

A: SHIJILIGHTING stands out for custom LED strip lighting. It’s great for B2B buyers needing OEM/ODM work. We set apart with quick sample sends in 3-5 days. We use fine chips like Epistar and San’an. Plus, we offer a full 2-year warranty. Our skill in mixing complex controls with custom parts makes us a top pick for global jobs.

Q: How to choose between DMX512 and SPI protocols for a project?

A: The choice depends on the scale and complexity of your installation. DMX512 is best for long-distance transmission and high stability in standard commercial environments, adhering to a universal industry standard. SPI is ideal for high-density pixel applications where individual control of every LED node is required for detailed video or animation effects, often used in conjunction with controllers like our SJ-M310RGB.

Q: Which IP rating is required for outdoor architectural lighting?

A: For outdoor architectural lighting exposed to rain but not submerged, IP65 or IP67 is generally sufficient. IP65 protects against low-pressure water jets, while IP67 allows for temporary immersion. However, for continuous submersion or extreme weather durability, IP68 utilizing silicone extrusion is the mandatory standard to prevent water ingress and UV degradation.

Q: SMD5050 vs SMD2835: Which is better for energy efficiency?

A: In most cases, SMD2835 leads for power savings and light per watt in fixed white or single-color uses. It’s built to handle heat better for its size. SMD5050 suits RGB color shifts since it fits three diodes in one spot. But for straight light and energy cut, SMD2835 is the current pick.

Q: What factors define a top-tier LED strip manufacturer?

A: A top-tier manufacturer must offer robust customization capabilities (OEM/ODM), strict quality control (aging tests and low defect rates), and rapid lead times. Key indicators include the ability to produce custom PCBs (e.g., 2oz copper), the use of branded chips (Epistar/San’an), and the provision of complete system solutions—including power supplies and controllers—rather than just selling standalone strips.